ENGINEERING

SPEED FROM PROTOTYPE TO PRODUCTION

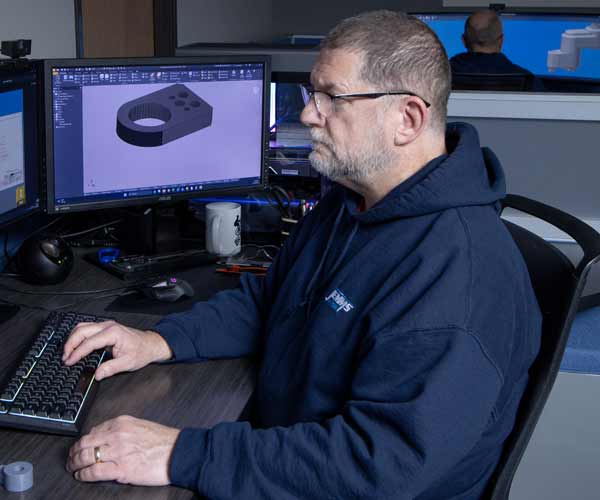

JEMMS engineering capabilities center on tools and expertise that accelerate development and boost performance. Their proprietary Gear Stress Calculator draws on 35 years of test data and field-proven results to deliver precise stress analysis, helping minimize wear, prevent failures, and optimize gear geometry and materials. This accelerates design cycles and produces more reliable, longer-lasting components.

An extensive design library of validated blueprints and CAD models enables teams to jump-start new projects with proven configurations, reducing development time and engineering costs. Complementing these resources, Jemms Inc.’s multidisciplinary design team evaluates each customer’s full process and applies creative, application-specific solutions. Their out-of-the-box approach ensures smooth integration, peak performance, and scalable results across any operation.

Experienced Design Team

- Multidisciplinary engineers

- Ability to solve complex application challenges

- Ensures seamless integration, peak performance

3D Printing

- Traditional prototyping methods can be time-consuming and costly. However, 3D printing offers a cost effective and efficient process for product development and validation.

- Jemms can quickly iterate and test designs, bringing custom products to market faster and more efficiently than ever before.

Request a Quote.